Minimize Lift Times and Maximize Efficiency with Lithium SAFEflex

Over an eight-hour shift, over three shifts a day, missed seconds can add up.

- How efficiency can your lift trucks get from A to B?

- How fast can it lift its load onto a loading dock, lift gate, or stack?

- How long can your lift truck move its maximum load, as its maximum safe speed, before being recharged?

- How long does it take to recharge your lift truck batteries?

The answer to these questions will determine the efficiency-and therefore, the cost-effectiveness-of your warehouse operations. Largely, the answer to these questions also depends on your lift truck batteries.

Lithium SAFEflex Provides a Competitive Advantage When Seconds Matter

- With like loads, lithium will beat lead acid every time.

- As lead acid discharges, its voltage drops.

- The longer lead acid works, the slower it runs

Green Cubes Technology Lithium SAFEflex batteries produce consistent voltage during every part of a charge cycle. Therefore, unlike lead acid batteries, lithium-powered lift mechanisms don’t slow down as they approach emptiness. Lithium-powered lifters will work until they need to be recharged-and they’ll recharge 5x faster than acid modules.

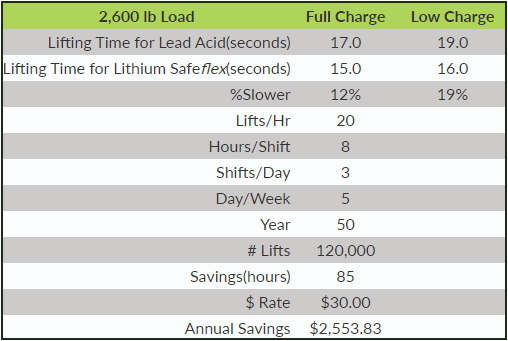

Hard Numbers on SAFEflex Efficiency

A Lithium SAFEflex battery can also pack in more capacity per kilogram. This makes Lithium SAFEflex-powered lifters lighter and therefore faster. In fact, using Lithium SAFEflex batteries makes vehicles so light that Green Cubes Technology is forced to add weight in order for lifts to meet ballast requirements.

Make Seconds Count with Green Cubes Technology

Lifting efficiency is only part of the picture where Lithium SAFEflex is concerned. Lead acid batteries can only be charged to 80% during the absorption/bulk charging phase and must be charged at lower currents to 100% to avoid damaging the battery. Understanding lead acid batteries causes reduced capacity and efficiency. Lithium SAFEflex batteries charge 5x faster than lead acid batteries of similar capacity.

When Seconds Add Up

2,600 lb LoadFull ChargeLow ChargeLifting Time for Lead Acid(seconds)17.019.0Lifting Time for Lithium Safeflex(seconds)15.016.0%Slower12%19%Lifts/Hr20 Hours/Shift8 Shifts/Day3 Day/Week5 Year50 # Lifts120,000 Savings(hours)85 $ Rate$30.00 Annual Savings$2,553.83

Each extra second it takes to lift or move a piece of material represents an added cost.When you calculate the extra time it takes to move material with a traditional lead-acid solution, for three eight hour shifts per day, you end up with 48,000 extra seconds per vehicle and that’s at a full charge. This number increases an additional 7% as the lead-acid battery nears the end of its charge. It’s time to get those seconds back. Contact Green Cubes Technology for more information.

DISCLAIMER Please note that everything posted on this site is up to date at the time of posting. Things change and products may be discontinued at any time. Please contact us for the most up to date information.