Visit Green Cubes at HIMSS Global Health Conference & Exhibition 2026, Las Vegas, NV March 9-12,

Overview

SAFEFlex is a drop-in replacement lithium-ion battery for lead acid battery power for electric material handling equipment. Temperature-controlled supply chain is more important than ever during with today’s volatile supply chain. On-line ordering of pre-prepared food, beverage clubs, and medicine distribution are all increasing the need for cold-chain technology. Lithium-ion batteries charge faster, and opportunistically, and have longer run-time than traditional lead acid batteries, optimizing equipment utilization Batteries don’t need to be swapped, watered, or equalized at room temperature, so maintenance is simplified. Cold-temperature cycle life is vastly improved for a lower total cost of ownership. This is a brief overview of how to implement and take advantage of this new technology.

The Cold Chain

Many products require constant refrigeration. Medicines, foods and beverages require cold transportation as well as storage and there is an increased strain on the cold storage industry as it adapts to increased fluctuations in response to on-line consumer habits, such as the new popularity of pre-prepared meal kits. For cold storage the insulated vehicle cargo area needs to be kept at a sub-zero temperature and the material handling equipment needs to operated within a refrigerated or freezer space.

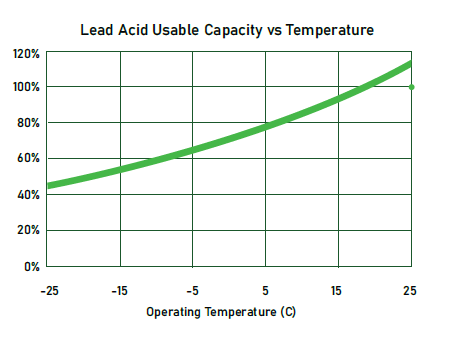

The Challenges of Lead Acid Batteries:

Electric material handling equipment is favored for

indoor environments, but traditional lead-acid batteries pose significant challenges, e specially at extremely cold temperatures. The extreme cold temperatures can cause the battery electrolyte to freeze which lowers the usable capacity of the battery, as seen in the accompanying graph, which uses information commonly provided by lead-acid battery manufacturers. In addition, there is permanent damage to the battery and greatly shortening the battery’s cycle life.

…In order to operate the material handling equipment at such a low temperature, the fleet is connected to an electrical grid at night, resulting in significant under utilization.

In addition to normal maintenance, watering and cleaning the acid residue typical of flooded lead acid batteries, traditionally, in order to operate the material handling equipment at such a low temperature, the fleet is connected to an electrical grid at night, resulting in significant under utilization. Charge time for lead acid batteries is long and time is required to equilibrate the equipment between temperature extremes. If care is not taken, condensation can occur on the equipment creating icy and dangerous conditions for workers.

Implementing Li-ion Technology:

Unlike lead acid cells, Li-ion battery packs offer a complete solution with integrated smart communication, charging, and heaters to keep the battery at an optimum temperature. Green Cubes Technologies’ Lithium SafeFlex is a drop in replacement for lead-acid batteries with excellent cold temperature performance, high cycle life and safe operation.

When the battery temperature is lowered, the intelligent control system enables the heaters to prevent the battery temperature from reaching a temperature too low to charge and prevent cell damage.

The charge system (or cables) can be brought into the cold storage area, so that the temperature equilibration is not required and there is no more risk of dangerous condensation. Full charge time is only one hour and charging can be performed opportunistically. The same equipment is used for multiple shifts with no down-time, so the number of vehicles required is lowered and operating costs are lessened.

The zero maintenance SAFEFlex makes it possible to forklifts and other material handling equipment without interruption.

SAFEFlex batteries increase the velocity of distribution businesses with existing fleets of MH equipment including Walkie Pallet Jacks, End Riders, Narrow Aisle Forklifts, 3-4 Wheel Counterbalance Trucks, large Turrets, and other equipment. When compared to traditional lead-acid batteries, lithium batteries charge faster, last longer, and deliver more usable energy with each discharge. Batteries don’t need to be swapped, watered, or equalized at room temperature, streamlining operations and increasing efficiency at cold storage facilities.

SAFEFlex enables 100% uptime and utilization of your material handling equipment in cold storage and sub-zero environments.

| Lead Acid | Li-Ion (LFP) | Advantage of Li-Ion Batteries | |

|---|---|---|---|

| Cycle Life | Low (~500-1000 cycles) | High (3000+ cycles) | Install battery for life of truck (no more swaps) |

| Charging Time | Slow (8 hours+) | Fast (60-90 minutes max) | Opportunity charge on-the-fly |

| Charge Efficiency | Low (~75%) | High (98%) | Lower electrical power costs |

| Energy/Volume Ratio | 80 Wh/L | 300-350 Wh/L | Smaller batteries |

| Energy/Weight Ratio | 30-50 Wh/Kg | 90-120 Wh/Kg | Lighter batteries & trucks reduce wear on power train |

| Partial Charging | Reduces battery life | No effect on battery life | Reduce down-time for battery charging |

| Consistent Voltage Output | Moderate | High | Extendes motor life, lowers motor maintenance |

| Depth of Discharge | Moderate | High | More run time per battery |

| Cold Temperature Performance | Low | High | More run time and less condensation in truck |

Advantages of SAFEFlex for Cold Storage Usage:

- There is no cold-temperature capacity loss with integrated battery heaters.

- One-hour fast charging is enabled within the cold storage area (to -40 degrees).

- Forklifts will never leave the freezer, and palletjacks can be charged in refrigerated trailers, so risks from condensation are minimized.

- A permanently installed battery can support 24/7 continuous operation with an opportunity charging regime.

- Maintenance is minimal, unlike lead acid batteries.

- Cycle-life enables a useful product life of up to ten years

- A distribution partner with the knowledge to implement and maintain the battery systems makes execution easy and seamless.

ABOUT GREEN CUBES TECHNOLOGY

Green Cubes Technology develops and manufactures a complete portfolio of lithium power systems that enable its OEM and enterprise customers to transition from Lead Acid and Internal Combustion Engine (ICE) power to Lithium-ion battery power. Green Cubes utilizes proven hardware and software platforms to build the most reliable lithium battery systems in its industries. With over 300 employees across six countries, Green Cubes has been producing innovative, high-performance, and high-quality products since 1986. For more information, email info@greencubestech.com or visit greencubestech.com.

DISCLAIMER Please note that everything posted on this site is up to date at the time of posting. Things change and products may be discontinued at any time. Please contact us for the most up to date information.