Overview

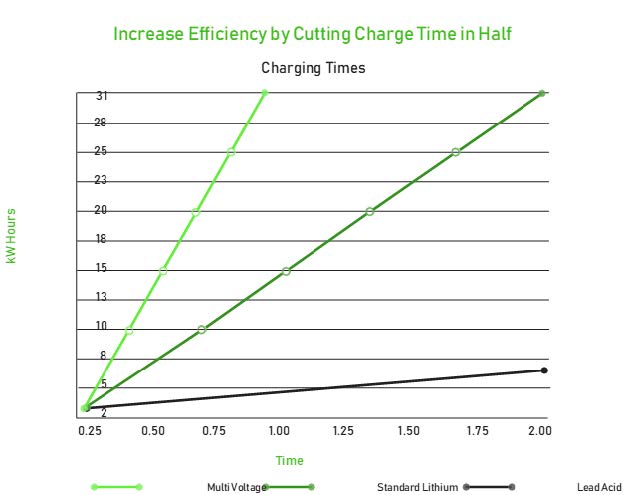

Opportunity charging is a practice applicable to both Lead Acid and Lithium-ion (Li-ion) batteries for motive power systems and especially useful for Material Handling (MH) equipment. These practices can be applied to all classes of MH equipment from small pallet jacks to 4 wheel forklifts to large turret trucks. Fast charging is a key differentiator for Lithium-ion batteries. Because the chemistry allows fast charging without damaging cycle life, Our Lithium SAFEFlex Li-ion batteries can be charged opportunistically during breaks and don’t require battery swaps. However, typical fast charging requires very high currents and two cables to accommodate the current with larger capacity batteries. Green Cubes Techology’s MultiVoltage SAFEFlex battery can be charged at twice the voltage, so dual cables are unnecessary and they can be charged in half the time.

The MultiVoltage SAFEFlex battery can be charged at twice the voltage, so they can be charged in half the time, bringing opportunity charging to the next level of convenience.

Charging Lead Acid batteries

For optimal cycle and calendar life of FLA batteries, manufacturers recommend that the daily cycle for batteries consist of:

- discharging the batteries fully

- charging at a C/5 rate

- resting for an eight hour cool down period

- equalize the battery on a weekly basis

Each battery experiences one full charge and discharge cycle per day. This conventional charge/ discharge regimen is reinforced by FLA battery manufacturers through warranties. With this maintenance one can expect to receive 500-1000 cycles from their FLA batteries before they start to experience permanent capacity fade.

FLA batteries can be opportunity charged (typically 25 Amps per 100 Amp-Hour or C/4 rate) and fast charged (typically up to 50 Amps per 100 Amp- Hour or C/2 rate), but these unconventional FLA charge regimens shorten or violate the manufacturer warranties.

The implication of this is that each piece of equipment used on a single shift may need one or two batteries for each vehicle. If the enterprise operates a multi-shift operation, then more than one battery is required per vehicle. So, at a minimum, multi-shift operations dictate a battery swap when the shift changes or the batteries need to be replaced more frequently than the warrantee period.

Charging Li-ion Batteries

Li-ion batteries are preferably charged using a Constant Current / Constant Voltage (CC/CV) charge regimen, but most MH equipment batteries are designed to accept both CC/CV and FLA charge regimens. Regardless of the state-of-charge of the battery when connected to the charger, the battery will efficiently accept the power and increase its state-ofcharge. Whether the battery has been connected to the charger for 15 minutes or two hours, that battery can be immediately discharged and used by the MH equipment as there is no need to cool or rest a Li-ion battery after charging.

The Li-ion cell chemistry has numerous chemical variants. Lithium Iron Phosphate (LFP) chemistry is the predominant chemistry used to power MH equipment: LFP features:

- exceptionally long cycle life (2000 – 4000 cycle to reach 80% of the original capacity)

- high power capabilities for both charge and discharge

- lower energy/density than other Li-ion variants.

The long cycle life means an LFP battery can be installed and remain in the equipment for 8-10 years. More importantly, since LFP chemistry can accommodate high power delivered to and from the battery, a depleted LFP battery can accept a full charge in a little over one hour (i.e. 1 C rate) and it can be charged throughout the shift when the operator has a break or lunch. Li-ion is the optimal chemistry for opportunity charging.

SAFEFlex MultiVoltage Batteries

Lithium SAFEFlex is a comprehensive battery solution designed to meet the cost, performance, efficiency and durability requirements of the rugged warehouse environment. It includes application-specific cell chemistry and intelligent battery management electronics. Lithium SafeFlex battery systems are high cycle life maintenance free solutions for industrial vehicles with fully customizable features to fulfill the most demanding requirements. The drop in replacement batteries make upgrading from Lead Acid to Lithium simple. The batteries are sized to fit the standard motive power lead acid battery, along with meeting the truck battery weight requirements.

MultiVoltage technology enables the battery to charge at double its output voltage, which cuts charging time in half and makes opportunity charging a more accessible option with simplicity and ease of use for the operator. The MultiVoltage battery completes a full charge in less than one hour and is offered in 24/48V, 36/72V and

48/96V combinations.

Green Cubes has deployed over 200 MultiVoltage batteries across these three different voltage combinations. It is common for high use and high capacity batteries, such as a large 48V battery, to be charged with two cables to increase the charge current. The MultiVoltage battery utilizes a single connector 4/0 cabling, which delivers cost efficiencies and minimizes the chance of cable damage over traditional fast charging with dual cables. Other than the battery configuration itself, the MultiVoltage battery uses standard chargers and requires no changes to the equipment.

Features of SAFEFlex MultiVoltage Batteries

Ease of Use

- 30 kWh, 48V 600Ahr battery can be full charged in less than 1 hour at 320 amps

- Configurable dot matrix battery discharge indicator provides critical battery information along with errors or other important runtime data

- No change to truck required, CAN communication for lithium ready equipment

- Utilizes existing 4/0 cabling

- No Maintenance

- No Watering

- No Equalization Charging

- No Battery Washing Needed

Safety & Protection

- Utilizes Lithium Iron Phosphate battery chemistry for increased safety and stability

- Voltage, Current, and Temperatures are continuously monitored by Green Cubes Technology’s custom Battery Management System (BMS) which controls the internal safety contactors or disconnects the fuse

- Constructed from UL approved components

Energy Savings

- Recharge efficiency of 98% or higher helps save electricity and minimal energy loss to internal heating extends battery life

- Improvements in runtime capacity efficiency of 10% or higher

- Charging at 2X voltage reduces power loss from component impedances

Flexible Design for Optimized Truck Applications

- Green Cubes Custom Battery Management System (BMS) offers over 100 parameters that can be adjusted for performance based upon the application.

- High Current Trucks with Accessories

- Low Temperature Storage Operations

- High Cycle Opportunity Charging

- Fully ballasted battery for heavy counterbalance trucks or non- ballasted batteries for light applications

- Exceptional charge management controlled by battery BMS is ready for CAN enabled chargers to further improve charge efficiency

Best Practices to Exploit Opportunity Charging

- Do a power study where the battery activity is monitored. Based on the data, one can determine whether there are adequate opportunities for charging throughout the shift. If there is no down-time for the equipment throughout the shift, then the batteries will need to be charged for an hour before the shift.

- Single shift vs. multi-shift operations can determine the value of opportunity charging. If the enterprise operates a single shift operation, a fully charged Li-ion (or FLA) battery should power that vehicle through the shift. When a second (or third) shift is needed, then opportunity charging can be used to recharge in increments and ensure that the equipment is powered through all the shifts.

- Rather than charging FLA batteries in a centralized battery maintenance room, distributed the Li-ion charging stations near break rooms and heavy work areas. Decentralized charging stations eliminate the operator’s travel time from their work area to battery maintenance room as well.

- Assess existing FLA chargers to determine if they are compatible with the Li-ion batteries.

- Assess the power output of the existing FLA and Li-ion charging infrastructure. The the power rating on the charger must be much higher when opportunity charging.

- Consider a multi-voltage battery if opportunity charging is desired but there is not adequate down-time within a shift.

MultiVoltage Battery Benefits

- High Cycle Life

- True Fast Charge / Opportunity Charge

- Drop In Lead Acid Replacement

- Passive balancing while in use equals NO DOWN TIME

- Standard charger cabling (single 4/0) with charging amperage of 320 amps

- Cuts out the expense of extra cables

- Reduce chance of cable damage

Applications

- Forklifts / Pallet Jacks

- AGV (Automated Guided Vehicle)

- Ground Support Equipment

- Industrial Electric Vehicles

Industries

- Distribution Centers

- Cold Storage

- Food and Beverage

- Pharmaceutical Warehousing

ABOUT GREEN CUBES TECHNOLOGY

Green Cubes Technology develops and manufactures a complete portfolio of lithium power systems that enable its OEM and enterprise customers to transition from Lead Acid and Internal Combustion Engine (ICE) power to Lithium-ion battery power. Green Cubes utilizes proven hardware and software platforms to build the most reliable lithium battery systems in its industries. With over 300 employees across six countries, Green Cubes has been producing innovative, high-performance and high-quality products since 1986. For more information, email info@greencubestech.com or visit greencubestech.com.