Understand Your ROI Potential Before Evaluations

Enterprises can achieve an increase in performance and a reduction in maintenance costs by switching from lead acid to our Lithium SAFEFlex batteries.

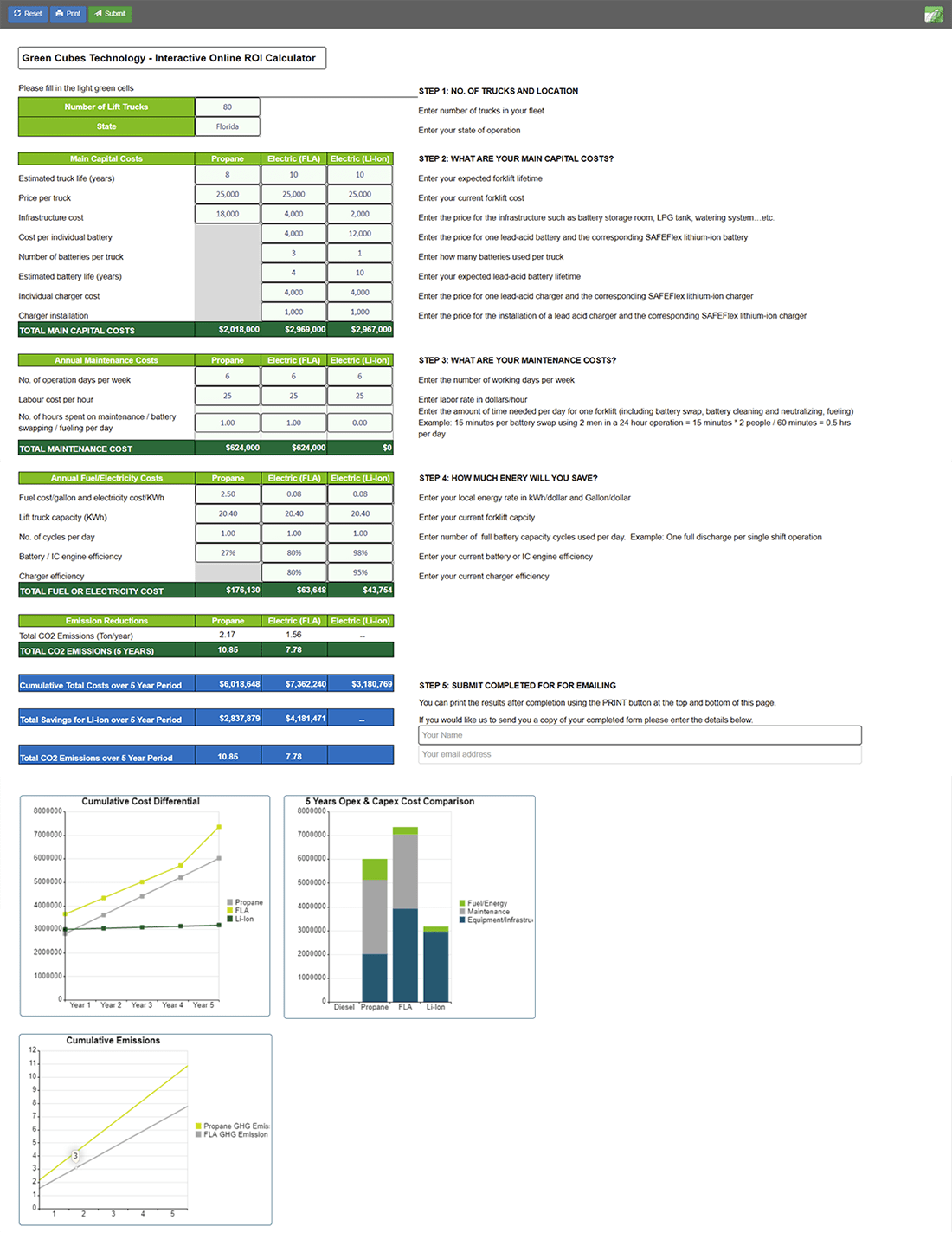

Green Cubes offers a free online Return on Investment (ROI) and Total Cost of Ownership (TCO) assessment that will be based on your specific fleet and facilities. The result of this assessment is we will identify areas of your operation where Lithium SAFEFlex batteries can make the most impact, as well as demonstrate the rate of return you can expect based on how you use your fleet.

You can enter your fleet information into our online ROI/TCO assessment to provide recommendations on upgrading your fleet to use Lithium SAFEFlex batteries. Our analysis is based on basic facility information like the number of vehicles, number of shifts, charging information, labor costs, etc.

Once our ROI/TCO assessment demonstrates the returns and you confirm these returns meet your internal thresholds for adopting new battery technology, Green Cubes will provide a risk-free trial of a battery/charger system, along with battery fleet monitoring software, so you can validate that the intended savings have been realized.

An example of the data we collect for the ROI/TCO assessment is shown to the right.

As an example, the assessment of an 80 truck evaluation over a five year period resulted in a $4.2M operational expense reduction.

In summary, Lithium SAFEFlex provides enterprise customers with immediate capital and operational savings when compared with lead acid batteries. This ROI with Lithium SAFEFlex can be achieved in less than a one year period and this has been repeatedly verified with our base of enterprise customers.

Listed below are the operational and capital efficiencies achieved by our enterprise customers.

- Increase in Productivity by 30% Minimum – Eliminate battery changes with faster charge times (from 100% DOD to fully charged in 1 hour).

- Lower Cost of Operation by 30% – Eliminate labor and time for battery changes and eliminating the burden of battery watering (every battery watered every 2 weeks).

- Lower Electrical Utility Cost for Charging – Lithium battery charging is 95% efficient vs. 80% efficiency with lead acid batteries. Lithium batteries do not need an 8 to 10 hour equalization charge once a week.

- Improved Safety Conditions for Associates – Eliminate battery changes and contact with battery electrolyte due to sealed “maintenance free” batteries.

- Improved Environmental Conditions – Eliminate lead acid batteries from your facility. Eliminate lead from your environmental footprint.

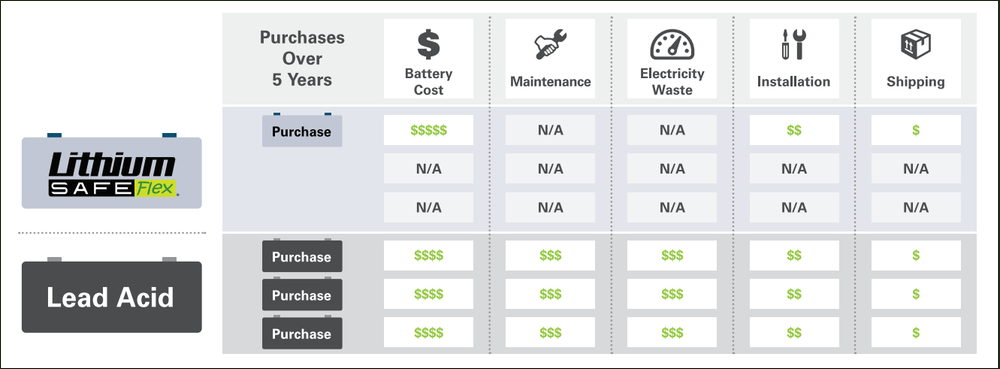

- Improved Asset Utilization – 100% utilization with lithium batteries (one battery per truck) vs. up to 3 lead acid batteries per truck (33% asset utilization with 1 battery in the truck and 2 in storage).

- Capital Cost Avoidance – Eliminate battery handling rooms, ventilation accommodations, eye wash stations and safety gear.

- Returned Floor Space – Eliminate battery rooms and re-allocate this area to become a staging area, additional pallet rack, break room, or maintenance shop. At a nominal $100.00 per square foot, these savings could be significant.

Register to use our Interactive ROI Calculator

To get your personalized ROI Calculation for converting your fleet over to Lithium Ion, please complete the form below and we will send you a link to access the calculator.