Rube Goldberg adjective

: accomplishing by complex means what seemingly could be done simply

a kind of Rube Goldberg contraption … with five hundred moving parts

— L. T. Grant

Source: Miriam Webster Dictionary

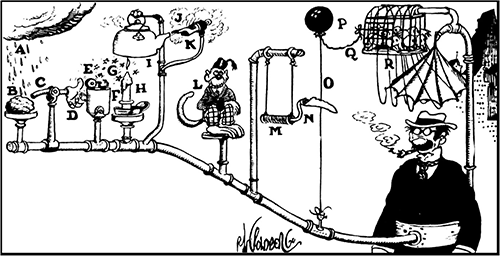

Did you know that Rube Goldberg is the only person to be listed as an adjective in the Miriam Webster Dictionary? The most celebrated cartoonist of his day, Mr. Goldberg often drew overly complicated machines used to achieve simple tasks to satirize industrialization and the self-destructive embrace of “progress.”

Comics such as “The Self Opening Umbrella” (shown above) show how a gentleman may rid himself of the inconvenience of opening an umbrella through the use of technology. Goldberg, who drew more than 50,000 comics in his lifetime and won a Pulitzer Prize for his work, often used these machines as a way to show how the “cure” of industrialization was much worse than the “disease” it aims to remedy.

If Mr. Goldberg were alive today, I wonder what he might make of the lead-acid battery (LAB) industry in general, and Exide Technologies in particular. If ever there was a Rube Goldberg Machine that required so much input for such little return, it would certainly be the LAB industry. The overly-complicated and destructive way they go about providing stored power would be comical if it weren’t so tragic.

Take, for instance, Exide Technologies. One of the largest manufactures and recyclers of LAB in the world, Exide would have you believe that their Total Battery Management — which they claim recovers 99% of lead — is a safe and sustainable form of energy. And if you look at the industrial battery market today, where LAB has a dominant 96% share, you’d think they still had a lot of people convinced.

But look a little closer and you’ll see that Exide’s contraption is just as ridiculous as the self-opening umbrella. In 2013, Exide was forced to close a LAB recycling facility in Vernon, CA after admitting to illegally storing, disposing, and transporting hazardous waste for more than two decades. Exide originally agreed to pay $50M to clean up the site, but it soon became evident that was not nearly enough. Cleanup estimates for that site alone were ballooning into the hundreds of millions of dollars — and that didn’t include medical costs for the tens of thousands of people potentially affected. There were also other sites in Florida, Georgia, Illinois, Indiana, Louisiana, Mississippi, South Carolina, Tennessee, Pennsylvania and Texas that had to be shut down because of environmental, leaving more than 50 derelict sites around the country.

Exide, by necessity, had to spend more and more of its resources fighting lawsuits and paying damages instead of operating their business and doing the necessary R&D work to drive innovation. And with no way to push those additional costs to consumers or partners, they were forced into bankruptcy in 2020. Now, everyone who has been negatively impacted by LAB over the last 150 years will want their day in court. And whether it be Exide Technologies or another LAB manufacturer, whether they are currently operating, or their derelict sites have been shuttered for years, the damage caused by lead pollution never goes away and a day of reckoning is coming.

The “Self Opening Umbrella” begins its chain-reaction series of events when:

Raindrops (A) fall on dried prune (B) causing it to swell and push against stick (C) which forces iron hand (D) to rub wheel against flint (E) in empty cigar lighter.

As a postscript, Mr. Goldberg adds “If you are hard up and can’t afford a new prune for each successive rainstorm, stay in the house and wait for the original prune to get old and wrinkled again.” With LAB manufacturers and recyclers faced with existential environmental and safety threats, maybe it’s time to ask how many prunes they have in reserve.

The moral of the story is this: now there is a way to punish for the past damages LAB manufacturers have caused. Anyone in the lead acid business will be increasingly hampered by these pressures until LAB is either outlawed or becomes financially untenable. Moreover, it is not only the lead acid manufacturers and recyclers at risk. Any company that uses LAB as part of their business — to power their forklifts or 5G networks — will become increasingly susceptible to disruption because of these factors. In other words – LAB’s Rube Goldberg Machine could soon become your problem. And that was Mr. Goldberg’s warning all along.

Keith Washington – CEO