Lithium battery maker Green Cubes Technology of the US announced a Swappable Mobile Power (SMP) portfolio of swappable lithium batteries.

Month: November 2022

Workplace: Green Cubes Technology Announces Swappable Industrial Battery for Mobile Workstation and Motive Product Manufacturers

Green Cubes Technology (Green Cubes), the leader in producing Lithium-ion power systems that facilitate the transition from lead-acid batteries and Internal Combustion Engine (ICE) power to green Lithium-ion battery power, announced its Swappable Mobile Power (SMP) portfolio.

MHI: Lead-Acid or Lithium-Ion: Batteries in Material Handling

Batteries are often taken for granted, but they can have an incredible effect on your distribution center or warehouse. Join us as we talk with Robin Schneider from Green Cubes about the batteries in your operation.

The New Warehouse: Green Cubes Technologies

On this special episode of The New Warehouse Podcast, we get an education on Lithium 101 with Robin Schneider, Director of Marketing at Green Cubes Technologies. Green Cubes is a power technology provider for customer OEM batteries, batteries for stationary equipment like data centers, and the motive business that makes batteries and chargers for material handling equipment and ground support equipment you would find at airports. If you are curious about lithium-ion batteries and what they can do for warehouses and material handling operations, you will want to tune in.

Green Cubes Technology Announces Swappable Industrial Battery for Mobile Workstation and Motive Product Manufacturers

Swappable Mobile Power (SMP) portfolio enables the electrification of mobile and motive products with swappable battery technology

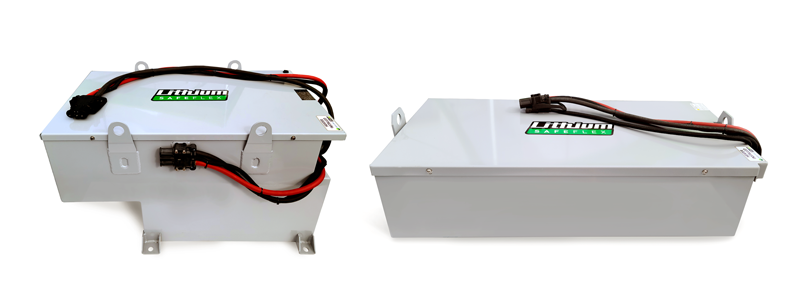

Green Cubes Technology (Green Cubes), the leader in producing Lithium-ion power systems that facilitate the transition from lead-acid batteries and Internal Combustion Engine (ICE) power to green Lithium-ion battery power, today announced its Swappable Mobile Power (SMP) portfolio. The SMP portfolio enables manufacturers to electrify their mobile and motive products utilizing swappable batteries with the leading Lithium-ion battery chemistry. At the center of the portfolio, the Swappable Industrial Battery (Industrial Swappable Batteries-1000) offers one of the highest Watt-Hour ratings for swappable Lithium Iron Phosphate (LFP) batteries on the market today.

Optimized for operator ergonomics and “hot” swapping of portable batteries, the SMP portfolio of products enables the electrification of non-powered mobile carts, such as industrial, medical or educational workstations. Additionally, multiple Swappable Industrial Batteries can be connected to power motive products with high torque requirements, such as Automated Mobile Robots (AMR), pallet jacks, or motorized sleds.

“Green Cubes pioneered the use of swappable batteries for mobile medical workstations and is the market leader in the production of swappable batteries for mobile industrial workstations,” said Mike Davis, Chief Revenue Officer for Green Cubes. “The Swappable Industrial Battery enables mobile workstation and motive product manufacturers to enhance the capabilities of their products and diversify their product line. This includes the electrification of non-powered workstations and motive products, as well as expanding the range of IT devices supported on existing powered workstations.”

The Swappable Industrial Battery is a 48 Volt, 20 Amp-Hour, 1000-Watt Lithium Iron Phosphate battery that offers exceptionally stable voltage under load, high capacity and power delivery in a small lightweight form factor. In addition to its ergonomic and ruggedized design, the watertight battery has an Ingress Protection (IP) rating of 65, which is optimized for both indoor and outdoor environments. Agency and safety approvals include UN 38.3 and IEC 62133.

To complement the Swappable Industrial Battery, the SMP portfolio has a suite of accessories to complete the integration with mobile workstations and motive products, including a battery receiver, power distribution electronics, AC/DC power supplies for charging and DC/AC power inverters to power mobile IT devices.

The SMP products are currently being evaluated by educational and industrial equipment manufacturers and their enterprise customers. Commercial availability is scheduled for the first quarter of 2023.

To learn more about the Swappable Mobile Power (SMP) portfolio; https://greencubes.com/product/industrial-battery-swib-1000/

About Green Cubes Technology

Green Cubes Technology develops and manufactures safe and reliable electrification solutions that enable its OEM and enterprise customers to transition from Lead Acid and Internal Combustion Engine (ICE) power to Lithium-ion battery power. Green Cubes utilizes proven hardware and software platforms to build the most reliable Lithium power solutions in its industries. With over 300 employees across six countries, Green Cubes has been producing innovative, high-performance, and high-quality power solutions since 1986.

Future-Proofing Your Fleet: Long term Viability of Li-ion Technology in the Material Handling Industry and Ground Support Equipment Industries

For nearly two decades, I have focused on battery technology and the battery industry. I have a PhD from The University of Texas at Austin, where I studied with John Goodenough, who won the Nobel Prize for inventing the Lithium-ion (Li-ion) battery. When I was in graduate school, in the late 90 and early 2000s, Li-ion batteries were not yet used commercially; laptop computers were powered by NiMH batteries and NiCd powered tools, camcorders and remote-control cars. GM had a robust research program on electric vehicles, which was ultimately canceled in 2002 because of poor market acceptance. No one knew which technology would power the emerging consumer electronics market- most thought NiMH batteries would stay as the default and big companies invested in everything from fuel cells to MEMs fly-wheels.

The Beginning of the Li-ion Battery Industry

Then, a number of key innovations resolved some of the safety concerns about Li-ion batteries, SONY commercialized the first Li-ion cells and the die was cast. Nearly all laptops were powered by Li-ion batteries within just a few years, and Li-ion batteries enabled cell phones which came on the market a bit later. The sheer volume of these two applications, enabled the market Li-ion battery market itself to mature, so that now nearly everything that needs portable or back-up power uses Li-ion. The only exception to this adoption is long term legacy lead acid stationary back up power and heavy equipment motive applications, like material handling and ground support equipment. Lead acid still has a lower up front cost and these applications don’t really benefit from the size and weight advantages of Li-ion batteries.

What will Happen Next in the Li-ion Battery Industry?

As motive applications like material handling and ground support equipment become the last hold outs for an older technology with a decidedly poorer environmental profile, I believe that we will see total costs for lead acid batteries increase. The infrastructure that is built up around the lead acid market (recycling, etc.) will shift to support the Li-ion battery industry. Li-ion batteries will have more suppliers and more diverse product offerings, more competition and more supply chain redundancy. Adjacent technology for Li-ion will improve and manufacturing methods will gain efficiencies. The US government is already beginning to invest heavily in strategic, domestic Li-ion manufacturing. When the governments of leading countries can start to ban and regulate Lead Acid, they will. In fact, RoHS and other regulations have specific call-outs for lead in batteries just because there has not been a viable alternative, until now. China has already begun to take drastic steps to completely ban lead acid battery manufacturing. Lead acid manufacturing will likely be only in far-away places with inexpensive labor and poor environmental regulations and high shipping and import costs. In the industry, there is no more debate about if Li-ion batteries will overtake Lead acid, the question is more when and how. The volume of Li-ion batteries being produced will be an advantage to the material handling and ground support industries long term, rather than a risk.

Will a New Technology Replace Li-ion Batteries?

The conversion of the entire industry from lead acid to Li-ion will be long, so you may wonder if there will be another, new technology that will leapfrog it, and my prediction is that there will not. Inventions in this science are very slow and tend to be incremental; it has taken China 25 years to get its mature Li-ion battery industry. If there were something coming up behind Li-ion batteries, it would already be far into development. I do believe that fuel cells will be a key part of the new zero carbon fleets, but they will replace ICE primarily and co-exist with Li-ion battery powered trucks. Because hydrogen infrastructure requirements are similar to gas and oil, it will likely be ten years before this technology is commonly available. In summary, Li-ion battery technology is going to be the de-facto standard in material handling and ground support equipment in the near future.