Visit Green Cubes at HIMSS Global Health Conference & Exhibition 2026, Las Vegas, NV March 9-12,

Manufacturing Operations

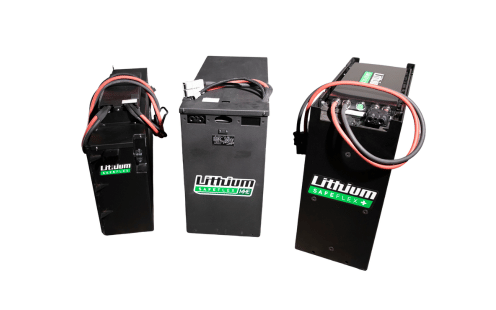

Portable Battery Packs

Green Cubes specializes in the development of portable battery systems, which are designed, verified and manufactured for superior run times, reliability, durability, safety and ease of use. With a proven track record of technical excellence, superior quality and on-time delivery, portable equipment manufacturers rely on Green Cubes to deliver power solutions for their portable device. Most equipment manufacturers strive to achieve maximum dependability and power efficiency by sourcing a battery and charger system that is customized to their application and device.

Green Cubes expertise extends across the full breadth of advanced portable power systems development; our battery experience ranges from cell characterization, verification and optimization, fuel gauges, battery management and SMBus communications.

Charging Systems

Green Cubes offers custom battery chargers and docking stations for portable and handheld devices. As a complete power system solution provider, Green Cubes has the fundamental battery chemistry knowledge that is the keystone of charger design. This allows Green Cubes to design and manufacture a charger that seamlessly integrates with the battery pack for exceptional ease of use and maximum energy delivery with a minimum charge time.

The Complete Solution

Battery and chargers can no longer be developed as isolated systems. They involve design teams to verify processes and capabilities at all phases of product development. At Green Cubes, our experts work with you from concept review and prototyping to final product.

When considering the selection of a battery and charger platform, OEMs should consider the advantages of sourcing both the battery and charger to a common vendor that is committed to reduce technical risk and minimize development costs. Several factors that OEMs should consider when assessing a supplier for both the battery and charger programs;

- Concurrent Designs with an Integrated Team – If a battery pack is developed by one vendor and the charger by a second vendor, both companies must integrate these two products together when each product is under development and undergoing changes. It is recommended that one company develop both products with a common, integrated development team that has constant communication (and file sharing) among themselves.

- Reduced Risk for Electrical Integration – A common design team for the battery pack and charger electronics will assure proper electrical operation/behavior during charge cycles. As an example, when SMBus communications is required, development time and cost is minimized when complete exposure of SMBus operation is available to engineers developing both the battery pack and charger.

- Tight Mechanical Integration – Using a common mechanical design team will assure tight mechanical integration between the battery pack and charger, which covers topics like cup holders, contact resistance, insertion/withdrawal and thermal management issues that affect both battery pack and charger as a system. This eliminates the risk of finger-pointing in the event of downstream issues.

- Consistent Industrial Design – Using the same vendors for the battery pack and charger enclosures ensures that product colors and textures are integrated and consistent. This is achieved using common vendors for injection molds, specifying identical textures, common vendors for custom-colored plastic resin material, common lots of raw plastic material and economies of scales with purchases of plastic resin.

- Lower Risk with Agency Approvals – If an OEM requires agency approvals on the charger, using Green Cubes to design both pack and charger will ensure that the charger will pass agency approvals with pack resident in the charger (i.e. eliminates risk of finger-pointing). This is especially applicable for radiated EMC testing and approvals.

Next Event

Latest News

Customer Ratings and Reviews

Green Cubes is a great company, great engineers, great product. That’s been kind of my number one go to [lithium] battery.

President Industrial Power Company

The thing I like about Green Cubes is that they have other lines of business outside of material handling batteries, they have been in the lithium world for a long time. I can trust they will likely stay in business

VP Industrial Battery Company

Green Cubes [differentiates] on its capability to custom design for things like the hardware, the firmware, and inverters. They also have economies of scale because they make battery systems for things like forklifts.

VP Powered Cart OEM

I am doing some work with them right now. We’re learning their products, and looking at demos. They have good people. They seem like they know the technology well – they say they’re a technology company. I like that they’ve been in the lithium business a long time. I can trust they will likely stay in business.

Sales Manager Industrial Battery Company

Green Cubes Technology would be my go-to for lithium applications.

Branch Manager OEM

I’ve told my friends at Green Cubes, I don’t plan on going anywhere. I believe in loyalty.