Our Marketing Engineer JD DiGiacomandrea contributed an article to Disaster Recovery Journal Magazine on why batteries for critical applications can sometimes fail when they’re needed most.

Blog

Mobile Europe: Why Lithium is Taking Over Stationary Energy Storage

Our Marketing Engineer JD DiGiacomandrea contributed an article to Mobile Europe Magazine on why lithium is taking over stationary energy storage.

AviationPros Podcast: Ground Support Worldwide Podcast

Our Director of Marketing Robin Schneider joined Ground Support Worldwide editor Josh Smith to discuss Lithium-ion battery technology and its use in ground support equipment.

Airports International Magazine: Green GSE – The Joys of Lithium

Our Director Business Development for GSE Jerry Crump was interviewed for an article in Airports International Magazine on how the adoption of lithium batteries has accelerated the electrification of GSE.

Material Handling Network: Green Cubes Technology Expands Executive Team

Green Cubes Technology, a provider in electrification and clean, connected, cost-effective power solutions, has announced four significant executive appointments to its leadership team – Ken Gregory as Vice President of Supply Chain and Procurement, Alan Forster as Vice President of Sales for Americas, Rita Faunce as Vice President of Sales Operations and Customer Experience, and Rocio Castellanos as International Controller. These executives join Ken Johnson, who was appointed Chief Operating Officer (COO) last year. The team will provide leadership to sales, supply chain, operations, manufacturing, and customer support functions for continued growth within Motive (including Ground Support & Materials Handling), Stationary (Telecom & Data Center), and Mobile (Industrial Automation) Power market segments.

“We’re very pleased to add so many talented professionals to Green Cubes’ executive team,” said Keith Washington, CEO of Green Cubes Technology. “This reflects the rapid growth of the company, and the leadership that each of these individuals bring to the company will help us continue to lead the charge to electrification.”

Mr. Gregory has a history of success with enterprise operations and transformation, customer experience, supply chain, and channel/alliance sales across the enterprise and consumer Information Technology,

Education, and Learning organizations. He has driven sustainable cultural and digital transformations in highly matrixed organizations resulting in increased revenue, enhanced customer confidence, organizational capability, and employee engagement. He brings over 25 years of core supply chain experience gained at IBM supporting its enterprise computer hardware segments. Mr. Gregory’s most recent experiences were at Pearson, a global leader in learning and education where he oversaw customer service and digital operations transformation.

Mr. Forster is responsible for managing and accelerating Green Cubes’ pipeline and revenue growth while developing its channel and sales enablement programs. In his recent role as Sales Director for the company’s Telecom and Data Center business unit (operating as Unipower), he helped rebuild sales and channel relationships, managed consistent quarterly growth, and increased sales channel coverage during the global pandemic. By working diligently with the Unipower team, he doubled bookings and revenue during a global supply chain and transportation slow down.

Ms. Faunce directs Green Cubes’ sales operations teams globally, drives its customer experience strategy, and will facilitate ownership of customer experience excellence. She has vast experience managing global teams in sales operations, customer service, and customer satisfaction with success in delivering customer-facing programs that foster a spirit of transparency, continuous improvement, and mutual accountability in customer relationships. Ms. Faunce will implement continuous improvement plans, leverage customer insights, and data, and work across multiple departments to ensure team members and leadership are aware of and dedicated to the goals of continuously improving the customer experience.

Ms. Castellanos joins Green Cubes as a key member of the global finance and accounting team. She is responsible for the internal and external financial reporting of all Green Cubes affiliated entities outside the U.S. In her role, she will support the entities in financial reporting topics and bridge the information to the U.S. headquarters. She will focus on continuous improvement of processes and deliverables to enhance financial performance visibility across the entities, as well as act as a strategic business advisor for International Operations. Ms. Castellanos brings over 20 years of experience and has worked for various companies including PwC, Swiss Life, and Daniel Swarovski Corp.

The expansion of Green Cubes’ executive team follows the company’s announcement last year that it added a second 36,000 square foot domestic facility in Kokomo, Indiana, and expanded its product lines for Motive and Stationary Power to support accelerated growth in Material Handling and Telecom markets. The Kokomo facility is currently increasing its manufacturing throughput and is expecting a 150% increase in Motive Power shipments in 2022, relative to 2021. Additionally, Green Cubes previously announced that it established two new facilities in Europe and a Technology Center in Zurich, Switzerland.

Read the original article at Material Handling Network.

Power System Design: Why Lithium is Taking Over Stationary Energy Storage

Today, you don’t have to look very far to find a device that is powered by a lithium-ion battery. Chances are, you’ve got one in your pocket, or sitting somewhere on your desk. You might be reading this article using a lithium-ion powered device! Lithium-ion batteries are the hidden power source behind billions of consumer products, everything from smartphones, tablets, and laptops to cordless power tools and digital cameras. Also, lithium-ion batteries are being developed and used as power sources for hybrid and self-driving vehicles, and finally are making a debut as energy storage solutions for electrical grids, wind turbines, and solar panels.

Lithium-ion batteries are well known to be smaller and lighter enabling portable devices to shrink and run longer. Now why would stationary applications, where space and weight are rarely an issue, benefit from a lithium-ion battery? Lithium-ion batteries have a few more benefits than just size and weight. These benefits include lower costs, higher reliability, increased flexibility, and remote monitoring. Telecom network, data center, and edge computing operators are finding these benefits fit their needs and are deploying more lithium-ion batteries than ever before.

The advantages of lithium-ion batteries often make them a more practical option for UPS backup power, especially in small-scale and remote deployments.

Reliable Power

The failure of lithium-ion batteries in UPS applications is extremely rare. Today’s battery providers utilize quality materials, superior design, and improved manufacturing methods to produce lithium-ion batteries that are built for reliability in all kinds of mission-critical environments. Research and investment in EV lithium-ion batteries has spilled over and benefits all lithium-ion batteries. Battery management systems (BMS) have evolved and improved over the past 20 years. These advanced BMS paired with modern cells create highly reliable backup batteries, as well as add monitoring, and advanced algorithms to monitor health of the cells.

Battery Management Systems are required on all Lithium-Ion batteries. Typically these are integrated into the design, and are the true differentiator between assemblers and integrators. Battery Management Systems can be extremely complex, monitoring voltages, currents and temperatures. They use this information to run algorithms that calculate the State of Charge, Time to Empty, Time to Full, and State of Health. Even more sophisticated BMS can operate thermal control systems, remote monitoring communications and even control energy conversion devices like inverters and chargers.

Since a BMS comes with every lithium-ion battery it is extremely attractive to Telecom, Network, and Data Center operators. No longer do you need to spend more on a separate BMS, integrate/program it yourself, and then try to find time to interpret the data. In today’s data centric world this functionality provides new value to operators.

Energy Density & Faster Recharge

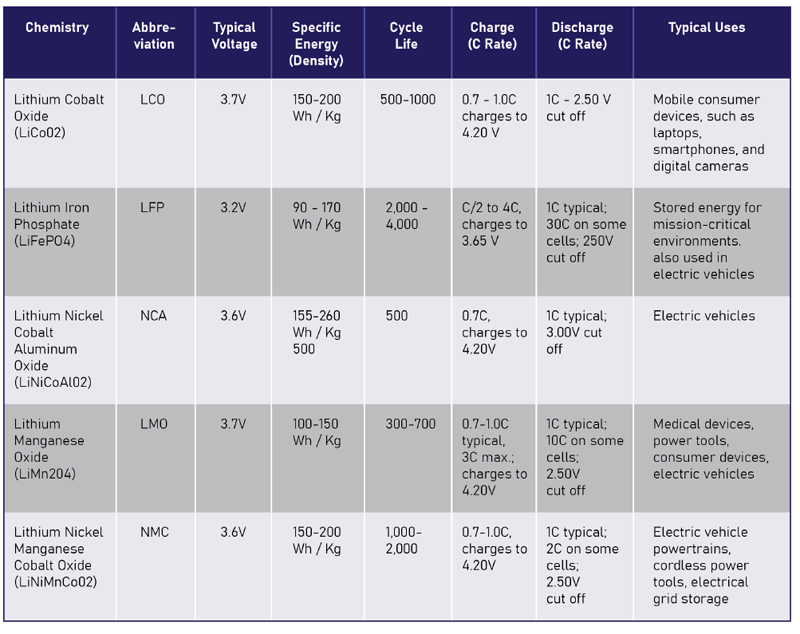

Lithium-ion batteries have a higher power density (watts per kilogram, or W/Kg) and energy density (watt hours per kilogram, or Wh/Kg) than lead acid batteries. They provide the same amount of energy in a lighter, more compact design. There are a few sub chemistries to choose from, as shown in Figure 1.

Also, most lithium-ion batteries can be recharged over 90% capacity in under two hours, while VRLA batteries may take anywhere from four to 24 hours to fully recharge. If an edge data center or 5G cell station has multiple utility outages in a single day, the lithium-ion batteries can quickly be recharged to provide ride-through time for each outage. Additionally, Lithium-Ion batteries can be paired with Solar, Wind, or fossil fuel generators to charge quickly and discharge slowly, optimizing energy harvesting when it is available.

Extended Lifespan & Cycle Life

Lithium-ion batteries have a lifespan of 10-15 years, which is 2-3 times as long as the average 5-7 year lifespan of lead acid batteries. A lithium-ion battery may easily last the entire 15-year lifespan of your UPS. Also, lithium-ion batteries have a predictable degradation curve, which makes it easier to determine when they are approaching “end of life” and will need to be replaced; unlike lead acid batteries, aging lithium-ion batteries are not subject to “sudden death syndrome.”

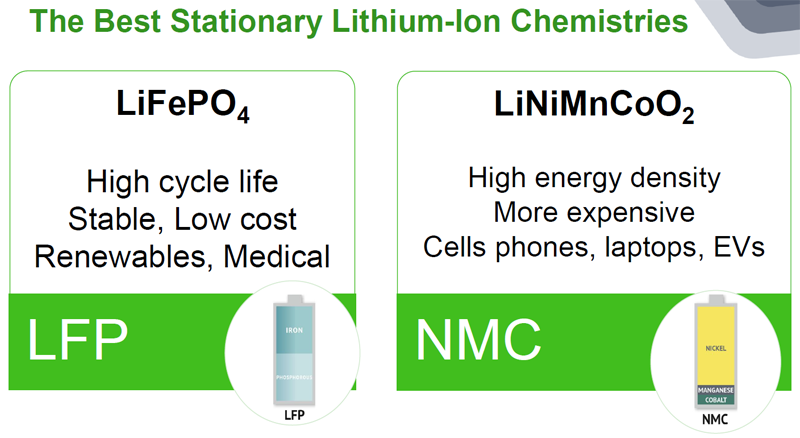

A typical lead acid battery has a cycle life of 200, meaning you can discharge the battery to 50% capacity and recharge it to 100% capacity, up to 200 times before the battery dies. But we know when you use a battery, you usually discharge it all the way to empty, damaging the lead acid battery. The lithium-ion chemistries used in batteries for UPS applications each have a longer cycle life – 1,000-2,000 cycles for the Nickel Manganese Cobalt (NMC) chemistry, and 2,000-4,000 cycles for the Lithium Iron Phosphate (LFP) chemistry. Figure 2 summarizes the uses and benefits of these two chemistries. Additionally, you can discharge lithium-ion batteries from 100% to 0%, which is twice the available capacity of lead acid batteries without doing any damage to the cells at all!

Smaller Size and Lower Weight

Lithium-ion batteries are up to 70% more compact than lead acid batteries. The smaller size of lithium-ion batteries makes it easier to install them in space-constrained deployments, such as modular or containerized data centers, 5G micro nodes, and data closets.

Also, lithium-ion batteries typically weigh about 1/3 less than most VRLA batteries. The lower weight makes lithium-ion batteries easier to carry, transport, and install, especially when delivering them to remote locations. Just talk to an installer, their knees and backs will thank you!

Temperature Tolerance

In outdoor settings, lithium-ion batteries can tolerate higher (and lower!) ambient temperatures, and are less susceptible to sudden temperature changes that would shorten a lead acid battery’s useful life. In indoor settings, lithium-ion batteries provide a savings in cooling costs, since server rooms and data closets can be kept at a higher ambient temperature without fear of damaging the batteries.

Less Maintenance

All lithium-ion batteries have a built-in Battery Management System (BMS) that monitors battery performance, reducing the risk of sudden battery failure. The BMS provides automatic status and fault monitoring, cell balancing, and power optimization for each individual battery.

A well-designed lithium-ion battery is virtually maintenance free, making it a “set it and forget it” solution. The BMS allows technicians to monitor battery health, in either a local or remote deployment. This allows you to maximize battery life, minimize downtime, and reduce labor and maintenance costs.

Cost Comparisons – Lithium-Ion vs. Lead Acid Batteries

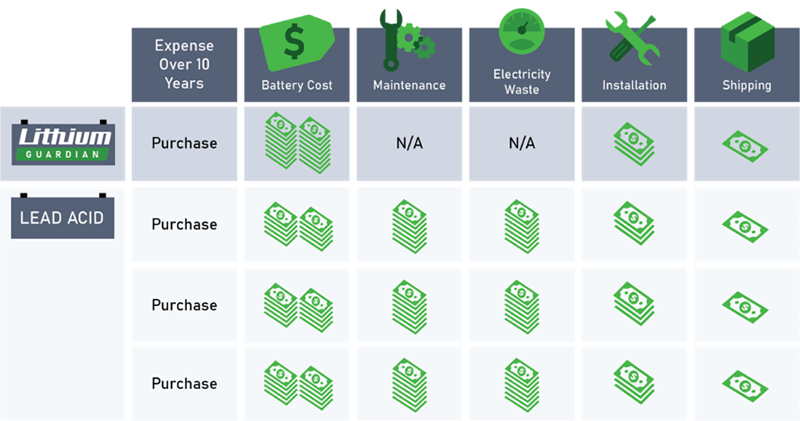

Although the costs have decreased significantly over the last decade, lithium-ion batteries can require a higher initial investment than lead acid batteries. However, depending on the costs of the application, lithium-ion batteries offer long-term savings in Total Cost of Ownership (TCO) when used in 5G and IT network deployments. Figure 3 shows some of the categories to consider when selecting a backup power chemistry for your long-term deployment. Each deployment is different, but stationary battery applications typically operate for very long periods, many more than 15 years.

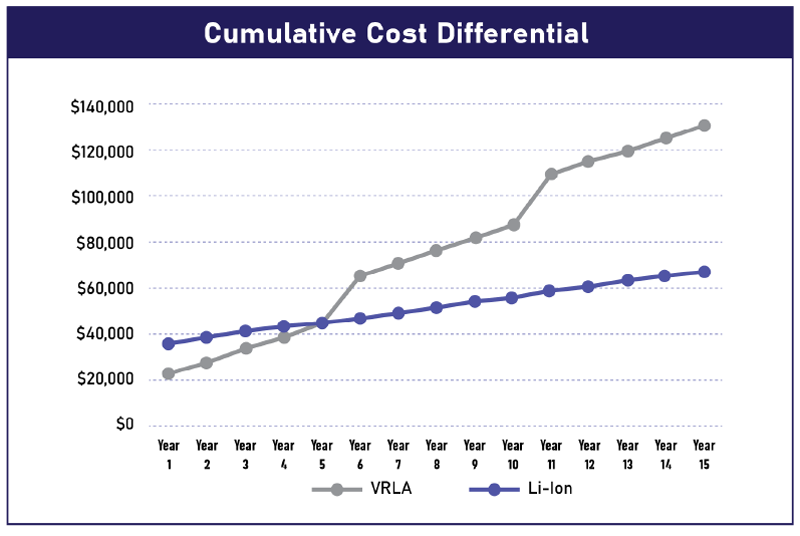

Figure 4 shows the cumulative cost differential over the 15-year lifespan that is typical of a UPS. While the initial costs of lead acid battery systems are lower, the total costs steadily increase over time, as the VRLA batteries must continuously be maintained and periodically replaced. Meanwhile, over this same period, the recurring costs of lithium-ion batteries are minimal, producing a Return On Investment (ROI) within five years of the initial battery deployment.

As mentioned, the longer lifespan and reliability of lithium-ion batteries means that they may last for the entire life of your UPS. This eliminates the cost of replacing batteries every few years, and also provides potential savings in labor, maintenance, shipping, and transportation that would otherwise be needed to service and replace the batteries in remote locations.

All in all, Lithium-ion batteries benefits for stationary applications are at a tipping point. Many network operators are considering lithium-ion batteries as a cost saving, higher performing alternative to the traditional Valve Regulated Lead Acid batteries they are used to using. Is it time to consider using Lithium-ion batteries to backup your mission critical loads?

Read the original article at Power System Design.

Workplace Material Handling & Safety: Better Batteries

The workhorse of your material handling equipment, batteries are quickly evolving into cleaner, better, longer-lasting models.

In the material handling world, batteries power a good portion of equipment—from most varieties of forklift trucks to AMR and AGV products. Computer carts for inventory management also depend on them. With such a central role to play, it’s important to understand what type of battery is best for your operations, how to maintain it and what the pros and cons are of the options.

Let’s start with those options. There are two common types of batteries used in material handling equipment: the standard lead acid and the newer lithium ion. The former has been around for hundreds of years and serves as the legacy battery. The latter came on the seen for material handling purposes just recently. “The technology for lithium ion was created in the 1980s, but it began with small electronic devices, like watches,” explained Maxim Khabur, Marketing Director at OneCharge. “It then moved to phones and computers, and eventually, lithium was ready for bigger formats.”

Think golf carts, forklifts and autos, where lithium now is growing in popularity. Still, while the option has been readily available for about eight years now, the material handling industry lagged in adoption rates. “Some businesses are a bit reluctant to do things different, however small the change, which is why the adoption of lithium power is not as fast as it could be,” said Khabur.

Robin Schneider, Director of Marketing at Green Cubes Technology, said that at the moment, lithium-ion batteries make up about 15% of the market. “We expect it to grow and replace most lead acid batteries over the next 10 years,” she said. “However, here are also new regulations, such as CARB, that will push general electrification and the elimination of fossil fuels. Diesel and propane are still very common, especially in outdoor equipment, but batteries and fuel cells will replace those, so it’s possible that both lead acid and li-ion batteries will grow in market share.”

As lithium options grow in availability, you’ll need to assess what best fits your particular operations. Weighing the pros and cons of each battery type will help you proceed.

Considering Costs

The grandaddy of batteries, the lead acid battery remains a popular choice in material handling. One big reason? Price. “The upfront cost to buy lead acid is still much cheaper than lithium,” said Kevin Ledversis, Sales Director at Newcastle Systems, maker of powered carts and workstations. “But over a lifetime, lithium will come out on top.”

Still, convincing end users of that fact remains the biggest battle for battery providers. “In the warehousing space, where most companies operate on a scale much, much smaller than an Amazon, they are less likely to invest in new technology,” said Ledversis. “In these cases, they may always look for the low cost of entry versus the ROI.”

For those that do want to look at ROI as the bigger factor, the numbers heavily skew lithium over lead acid. Khabur’s numbers look like this: Over a five-year period, where an operation runs 14 lift trucks on three daily shifts, lithium batteries will cost 35% less than lead acid.

The reasons behind the lower overall lifetime cost add up through several contributing factors. Maintenance is one of them, as is the time lead acid batteries must spend out of the equipment, they power in order to charge. “Lithium-ion is maintenance free once it’s set up, has a much longer life cycle and can be fast charged,” said Schneider. “This makes it generally more cost effective over a few years’ time frame.”

Lead acid batteries also require real estate in your facility in the form of a separate charging room. “There’s a cost associated with that in the form of the ventilation required,” said Khabur. “There’s also about 30% extra electricity needed to charge a lead acid battery. The dollars add up.”

There’s also a safety factor to consider. “There are fewer injuries involved with lithium batteries,” explained Khabur, “compared to lead, which must be swapped out.”

You’ll want to consider the sloppiness of lead batteries, too. Acid spills on floors and trucks develop into corrosion, one more hazard associated with lead acid batteries.

Looking Forward

With the labor shortage in full swing—with no signs of slowing down—robots have more than proved their worth and ROI. “Robots are growing astronomically and all of them run on lithium batteries,” said Ledversis. “They are also smart enough to know where their home is and to return there for charging.”

These factors combined with many others point to a brighter future for lithium over lead acid. “Anything you power to move will be using lithium going forward,” said Ledversis. “Equipment will only become smarter and easier to use, and lithium batteries fit those applications.”

There are a few varieties of lithium-ion batteries to consider, if that’s the direction you are headed. Lithium iron phosphate (LFP) and nickel, manganese and cobalt (NMC) are examples—the former tends to feature a longer life cycle and higher power delivery, whereas NMC is more common in consumer products. MultiVoltage, a proprietary technology from Green Cubes, products are another variety and can be charged in less than an hour.

As the material handling world focuses on more sustainable options, lithium will offer the features most companies are looking for. A reduced carbon footprint, fewer fumes and acid spills and the elimination of battery charging all make lithium a greener option than its predecessor. The future will likely see everything from forklifts to robots, sweepers/scrubbers, carts, and the like powered by lithium. It may take several more years to reach that breaking point, but battery makers are confident the day is coming.

“When you add up performance, safety, sustainability and costs, lithium comes out ahead,” said Khabur. “For the material handling industry, that’s what it’s all about.” WMHS

By: Christian Dow, Contributor

Read the original article at Workplace Material Handling & Safety.

Li-ion Cells are Growing – When Does it Stop?

There has been a lot of talk lately about new lithium-ion factories coming online and even more planned. What are they building though? Manufacturers are looking at how the size of the cell used in these EV’s can influence performance and Tesla’s new Giga factory in Austin Texas just began rolling vehicles off the line powered by a new Lithium-ion cell. Now Panasonic has delivered their first larger cells to Tesla in June, and they are big!

Figure 1: Lithium-Ion cells from Panasonic in three assorted sizes.

The first commercialized Lithium-ion (Li-ion) cells were cylindrical in shape. This allowed for high-speed automated manufacturing processes to be used. The original size was 18 milimeters in diameter and 65 millimeters in length (the 18650 form factor, the trailing 0 means it is a cylindrical cell, as square cells would have a third number here). These dimensions allowed for the first commercial laptops to use Li-ion cells and remain fairly slim. As the industry matured, and manufacturing ramped up to build more cells for applications, we learned that making bigger and longer cells can lower the cost of cell manufacturing. The standardization of the 18650 cell form factor spread across many industries and cemented it as the de facto shape and size.

To achieve the cost savings, a new size emerged, the 21700 cell. This introduced a 50% increase in capacity with only a 15% increase in diameter. Tesla led the charge and soon all of the major Li-ion cell manufacturers began to produce their own 21700 cells. Not only did this help increase the ratio of active material to packaging, delivering higher capacity, it also provided more active surface area for the lithium-ion exchange to occur. These cells deliver higher current and better performance.

In 2020, at Tesla’s Battery Day event, Elon Musk and Sr. VP of Powertrain and Energy Engineering Drew Baglino, introduced the world to the “perfect size”. The Tesla duo introduced the 4680 form factor (Dropping the last zero, per Elon, “Nobody could explain to me why there was an extra zero. So I… said, okay, well, we’re deleting the zero”). This new cell is 8x the size of an 18650 and provides more capacity due to the increased ratio of packaging to active materials. According to Tesla, this is the perfect size based on their analysis of the chemistry, construction methods, application needs, and manufacturing capabilities.

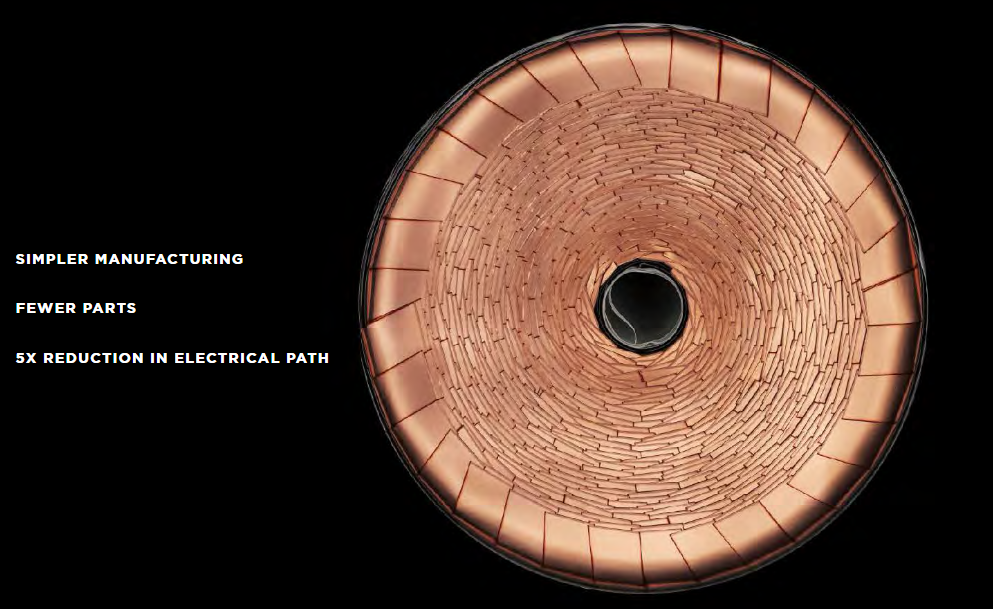

Figure 2: Tesla’s new 4680 cell

However, here are a few problems with this new form factor that will need to be solved to commercialize and ramp production. The innovation Tesla presented to solve many of these challenges is a new “Tabless” cell concept. This is multi-tab design that resembles a shingled spiral of tabs that have been laser cut on the side of the anode and cathode. What does this design do for performance? This significantly reduces the electrical path thus reducing the internal resistance of each cell, allowing the larger cells to discharge and charge quickly without generating hot spots internally and reducing the heat generation in each cell in general. This improves upon the incumbent design most cell manufacturers use today that require 1-3 tabs be placed on the anode and cathode strips, which can be over a meter long, to transport current form the active materials to the contacts on the cell.

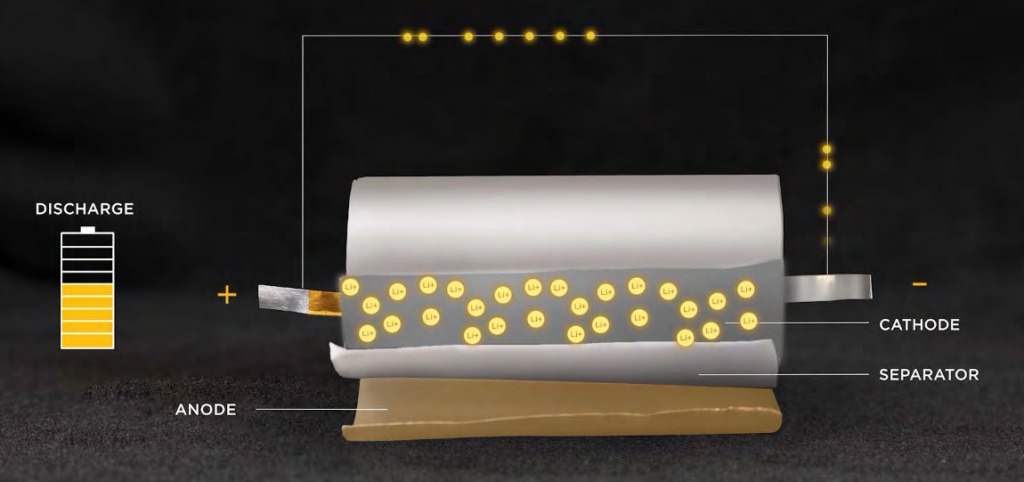

Figure 3: The Jellyroll and tabs in a typical lithium-ion cell

Figure 4: Looking into end of the jelly roll, this is the “Tabless” design

The clever Engineers over at Bosch Research have long thought there could be advantages to this type of mechanical approach and went the extra mile to simulate it! Their research is fascinating; they found this approach to achieve a 10% improvement in 18650s and even more in larger cells enabling higher charge rates, and most significantly reduces heat generation, resulting in lower cell temperatures.

How big is too big? The limiting factor indeed seems to be the heat rejection in the cell. Now that the heat generation has been reduced through the “Tabless” design, all cell manufacturers must determine what the optimal cell diameter is. The Bosch Engineers thought of this as well and have conducted studies to create models of the heat rejection from inside the cells. This is where Tesla, Samsung, LG, Panasonic and other manufacturers are limited in size. The rate at which heat is rejected radially is much lower than longitudinally due to the materials used in the anode and cathode of the cells. The “Tabless” design will increase the heat rejection rate longitudinally even more, but where is the sweet spot in terms of diameter? Bosch has developed the software to simulate these complex interactions, but it seems that Tesla has decided that sweet spot is at 46mm diameter, and 80mm of length.

The first 4680 cells are rolling off the line at Tesla Austin, and other manufacturers are being urged to speed up their development of this form factor as well. It seems for now that 4680 is the right size and the length of time between standard industry size evolutions is decreasing. Green Cubes is a cell agnostic Lithium Battery Manufacturer. We can use any size cell and benefit from the economies of scale, performance improvements, and diversification of supply to best serve our customers. Green Cubes is leading the charge to modern electrification using the best cell for the job.

If you would like to learn more about Bosch Research simulations, read Jake Christensen’s blog post.

If you want to know more about Tesla’s new batteries, read this article.

Green Cubes Technology Expands Executive Team

Industry Leader Expects Accelerated Growth from Continued Demand for Industrial Electrification

Green Cubes Technology, a leader in electrification and clean, connected, cost-effective power solutions, today announced four significant executive appointments to its leadership team – Ken Gregory as Vice President of Supply Chain and Procurement, Alan Forster as Vice President of Sales for Americas, Rita Faunce as Vice President of Sales Operations and Customer Experience, and Rocio Castellanos as International Controller. These executives join Ken Johnson, who was appointed Chief Operating Officer (COO) last year. The team will provide leadership to sales, supply chain, operations, manufacturing, and customer support functions for continued growth within Motive (including Ground Support & Materials Handling), Stationary (Telecom & Data Center), and Mobile (Industrial Automation) Power market segments.

“We’re very pleased to add so many talented professionals to Green Cubes’ executive team,” said Keith Washington, CEO of Green Cubes Technology. “This reflects the rapid growth of the company, and the leadership that each of these individuals bring to the company will help us continue to lead the charge to electrification.”

Mr. Gregory has a history of success with enterprise operations and transformation, customer experience, supply chain and channel/alliance sales across enterprise and consumer Information Technology, Education and Learning organizations. He has driven sustainable cultural and digital transformations in highly matrixed organizations resulting in increased revenue, enhanced customer confidence, organizational capability, and employee engagement. He brings over 25 years of core supply chain experience gained at IBM supporting its enterprise computer hardware segments. Mr. Gregory’s most recent experiences were at Pearson, a global leader in learning and education where he oversaw customer service and digital operations transformation.

Mr. Forster is responsible for managing and accelerating Green Cubes’ pipeline and revenue growth while developing its channel and sales enablement programs. In his recent role as Sales Director for the company’s Telecom and Data Center business unit (operating as Unipower), he helped rebuild sales and channel relationships, managed consistent quarterly growth, and increased sales channel coverage during the global pandemic. By working diligently with the Unipower team, he doubled bookings and revenue during a global supply chain and transportation slow down.

Ms. Faunce directs Green Cubes’ sales operations teams globally, drives its customer experience strategy, and will facilitate ownership of customer experience excellence. She has vast experience managing global teams in sales operations, customer service, and customer satisfaction with success in delivering customer facing programs that foster a spirit of transparency, continuous improvement, and mutual accountability in customer relationships. Ms. Faunce will implement continuous improvement plans, leverage customer insights and data, and work across multiple departments to ensure team members and leadership are aware of and dedicated to the goals of continuously improving the customer experience.

Ms. Castellanos joins Green Cubes as a key member of the global finance and accounting team. She is responsible for the internal and external financial reporting of all Green Cubes affiliated entities outside the U.S. In her role, she will support the entities in financial reporting topics and bridge the information to the U.S. headquarters. She will focus on continuous improvement of processes and deliverables to enhance financial performance visibility across the entities, as well as act as a strategic business advisor for International Operations. Ms. Castellanos brings over 20 years of experience and has worked for various companies including PwC, Swiss Life and Daniel Swarovski Corp.

The expansion of Green Cubes’ executive team follows the company’s announcement last year that it added a second 36,000 square foot domestic facility in Kokomo, Indiana, and expanded its product lines for Motive and Stationary Power to support accelerated growth in Material Handling and Telecom markets. The Kokomo facility is currently increasing its manufacturing throughput and is expecting a 150% increase in Motive Power shipments in 2022, relative to 2021. Additionally, Green Cubes previously announced that it established two new facilities in Europe and a Technology Center in Zurich, Switzerland.

About Green Cubes Technology

Green Cubes Technology develops and manufactures safe and reliable electrification solutions that enable its OEM and enterprise customers to transition from Lead Acid and Internal Combustion Engine (ICE) power to Lithium-ion battery power. Green Cubes utilizes proven hardware and software platforms to build the most reliable Lithium power solutions in its industries. With a global footprint across six countries, Green Cubes has been producing innovative, high-performance and high-quality power solutions since 1986.

5G Technology World: Battery Backup Chemistries for 5G Small-Cell Sites

As the number of cell sites increase and their sizes decrease, engineers have options to consider for battery backup. Differing battery chemistries offer more choices and different performance levels. Selecting the right battery chemistry for each application is critical to ensure reliable, long lasting, and cost-effective power delivery. Green Cubes Engineer JD DiGiacomandrea discusses the attributes that affect battery selection in an article published by 5G world.

Read the full article in 5G Technology World