Product chosen from thousands of award nominees that redefine their markets for a smarter, more efficient manufacturing world.

Green Cubes, the leader in producing Lithium-ion (Li-ion) power systems that facilitate the transition from lead-acid batteries and Internal Combustion Engine (ICE) power to green Li-ion battery power, today announced its Lithium SAFEFlex Battery Charger was named a New Equipment Digest Magazine Innovation Award winner for the Electrical and Electronics Category.

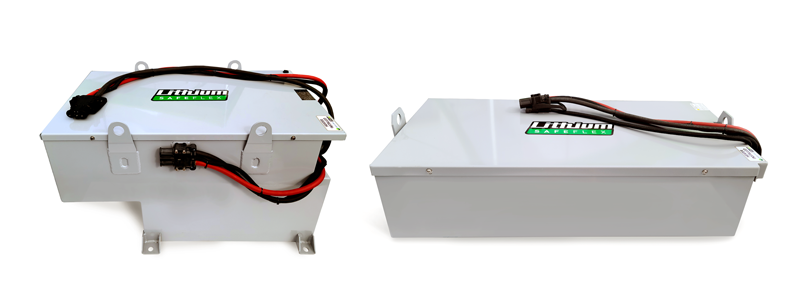

The Lithium SAFEFlex Chargers, announced earlier this year, were developed to complement Green Cubes’ market leading Lithium SAFEFlex Batteries. Green Cubes is the only manufacturer to offer enterprises both Lithium-ion batteries and affiliated Li-ion chargers to the Material Handling industry, thus simplifying the electrification of Material Handling equipment. These chargers are offered in 15 Kilowatt (kW) and 30 kW models. Each model supports up to three simultaneous charging ports and performs voltage auto-detect for each of the charging ports. Efficient Li-ion charging of multiple trucks lowers utility costs for enterprise customers.

“For the past 85 years, New Equipment Digest has been bringing the world information about not just the best equipment from the best suppliers, but also the newest, freshest designed equipment makers have developed to produce ever stronger, smarter, and more efficient tools for the manufacturers who depend on them,” said Laura Davis, editor for the magazine. “This process is really what is at the heart of NED and exactly what we look for as we curate material for every new issue—its innovation in its purest, most material form.”

The NED innovation Awards program, now in its sixth year, is an annual contest that evaluates thousands of innovative new products published over the course of 12 months to recognize those few that best represent the potential in the market. Products that fundamentally change their markets, crush limitations of their product class, and redefine design possibilities are nominated for the awards.

About Green Cubes Technology

Green Cubes Technology develops and manufactures safe and reliable electrification solutions that enable its OEM and enterprise customers to transition from Lead Acid and Internal Combustion Engine (ICE) power to Lithium-ion battery power. Green Cubes utilizes proven hardware and software platforms to build the most reliable Lithium power solutions in its industries. With over 300 employees across six countries, Green Cubes has been producing innovative, high-performance, and high-quality power solutions since 1986.