Overview

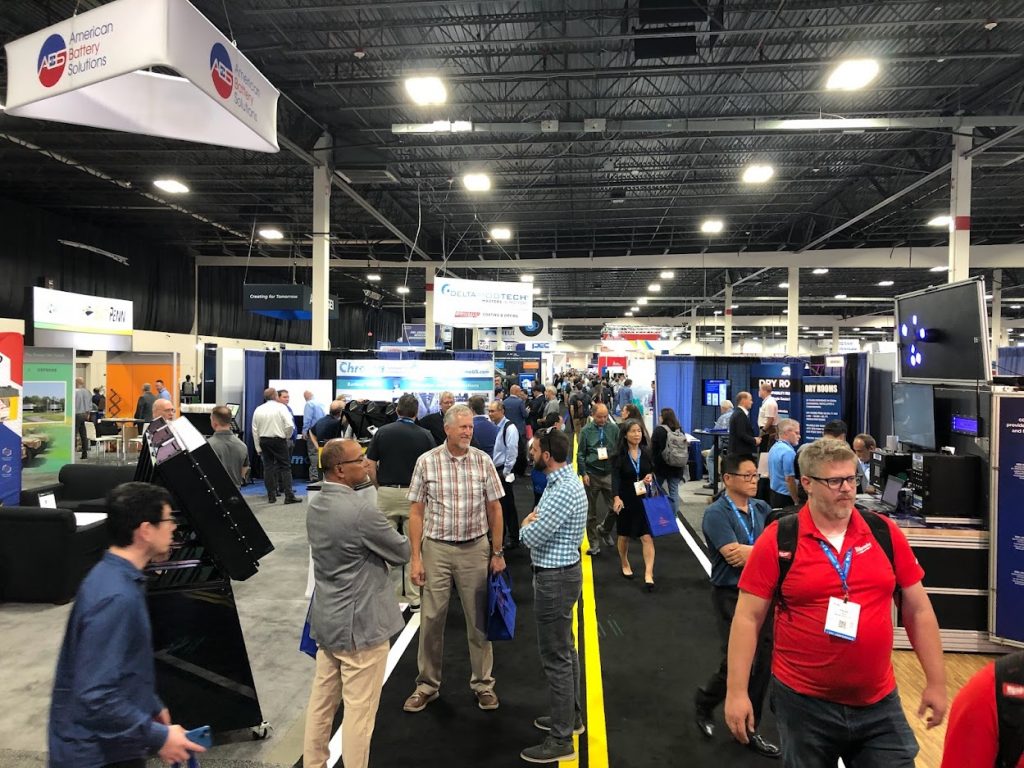

Listed below are interesting announcements and observations from our team that was deployed to The Battery Show last week in Novi, Michigan. We want to provide the entire battery community with trends and new announcements that may influence their product and partner choices in industrial electrification. This year, the crowds were crazy, which lead to many queues for basic necessities such as parking and on-site food.

https://www.thebatteryshow.com/en/home.html

Echotec

EcoTech announces and displayed their new 5 kW Ecopoint HF1 motive Li-ion battery charger. It has an efficient High Frequency single phase input of standard 190 thru 240 VAC input voltage range, and near unity (0.99) power factor. Great charger for palate jack batteries, walkie batteries and AGV batteries. And as always, Ecotech is one of the few motive chargers that has most of their products in stock. https://ecotecbatcharger.com

To learn about Green Cubes’ similar Li-ion battery charger go to: https://greencubes.com/product/lithium-safeflex-chargers-fbc-series/

Phihong

Phihong is one of the leading OEM/ODM EV battery chargers in Asia. Their products include Level 3 DC charger ranging for 30 kW to 480 kW, and Level 2 AC charger ranging from 32 to 80 Amps. They had an impressive array of motive Li-ion battery chargers and EV Li-ion battery chargers on display in their booth. OEM Chargers on display included chargers they developed for Shell, Bosch, Audi, Jaguar, and Taiwan Cement Corporation. https://www.phihong.com/ev-chargers/

Lithion

Lithion manufactures the Lithium Iron Phosphate (LFP) Valence brand of modules and battery packs, formerly manufactured by Valence Corporation. Along with the array of 12V, 24V, and 36V standard format batteries offered by Lithion, tucked away in a small corner of the booth, they did have samples of their new LFP cylindrical cells. Although I did not measure the size of the cells, presumably they will offer 26650 format cells. Looking forward to the production release of these cells next year. https://www.lithionbattery.com/

To learn about Green Cubes’ standard format LFP batteries go to: https://greencubes.com/products/batteries/

East Penn and Navitas

East Penn had an impressive array of the Deka brand of Flooded Lead Acid (FLA), Sealed Lead Acid (SLA), sealed gel, TPPL batteries on display in their booth. And a portion of the booth was allocated for the Navitas brand of motive batteries, which are being rebranded as Deka Ready Power batteries. It is interesting that East Penn attends an EV trade show with lead acid batteries. It makes you wonder how committed they are to embracing lithium-ion batteries, or are they trying to delay the inevitable ? https://www.eastpennmanufacturing.com/

CATL

CATL partner CSI had a wide variety of EV components on display. This included many pre-engineered Li-ion battery packs to fit any number of applications, over 300 types I was told by their Sales team. They also offer many automotive components that have been sourced and customized to seamlessly integrate with their battery packs, making EV’s much easier and faster to design. They didn’t have any Sodium Ion batteries (SIB) on display, but did mention that CATL is working on this next generation chemistry. http://www.coulombsolutions.com/

EVE

One of the premier Li-ion battery cell vendors EVE had a large booth and an even larger presence on the floor. EVE was showing off their impressive line of LiFePO4 Lithium Iron Phosphate (LFP) chemistry cells, and battery modules. EVE continues to grow their presence in North America as a quality cell and battery manufacturer. https://www.evebatteryusa.com/

LithiumWerks

An exciting showing for LithiumWerks, as they have just recently been acquired by a firm out of India, Reliance. They are producing two very powerful cylindrical cells, with high discharge rates, and excellent cycle life. Reliance is the largest Energy conglomerate in India, and LithiumWerks is poised to provide energy storage to the global market. https://lithiumwerks.com/

To learn about the difference between NMC and LFP go to: https://greencubes.com/about-us/types-of-lithium/

Energy Assurance

With all the new Li-ion cell and Li-ion battery vendors at the show, there were some excellent testing partners to help with qualification. Aside from the normal Intertek, UL, SGS labs, there was Energy Assurance at the show, who operates multiple labs across the US, including the old A123 facility in Massachusetts. With impressive testing capabilities, a new 20,000 sqft lab and a focus on customers Energy Assurance will be growing in the next years for sure. https://www.energy-assurance.com/