Green Cubes Technology today announced broad company expansion and rebranding to capture the new scope and scale of the company. Green Cubes added North American facilities, established operations in Europe and is expanding product lines for the Material Handling and Data Center markets.

Increasing industrial output and e-commerce is a key factor driving global demand for material handling equipment, and there is continued demand for online data storage that started with digital globalization and is exponentially increasing with the remote workforce. At the same time, green initiatives are gaining public and private support. While the need to decrease fossil-fuel dependency gets attention, green power storage – in the form of Lithium-ion batteries – is a necessary complementary technology.

“Expansion of warehouses and capacity across the globe has been fundamental to the global material handling battery market trends observed in the recent years,” said Christophe Pillot, Partner and Director of AVICENNE Energy. “As organizations recognize the potential to reduce total cost of ownership and meet green initiatives, we will see Li-ion based systems move further into the mainstream, specifically for 24/7 operations where the value proposition of the technology is easily recognized.”

“Our vision is to design platforms to help accelerate the adoption of clean energy technologies to improve enterprise customer performance,” said Keith Washington, President and CEO of Green Cubes. “In a remarkable confluence of events, the growth in both e-commerce and online data storage are timed alongside accelerated demand for green solutions.”

Green Cubes is responding with technology innovation and manufacturing scale to meet these needs on a global level. It recently expanded its engineering and production facilities in Kokomo, Indiana. In addition to the existing facility, Green Cubes added another 36,000 square foot facility. The existing production facility will continue provide Lithium-ion batteries for the mobile medical workstation market, while the new facility houses engineering staff and produces Lithium-ion material handling batteries.

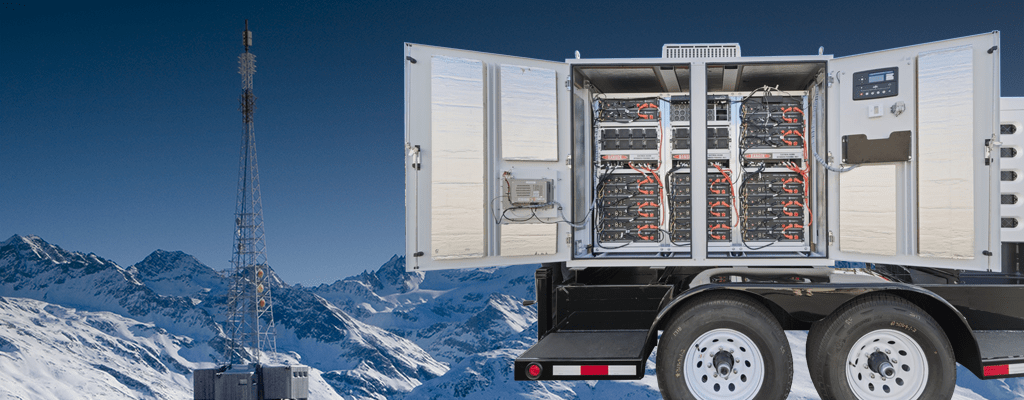

Additionally, Green Cubes established two new facilities in Europe to better serve its growing overseas customer base. A new Technology Center is located in Zurich, Switzerland. This facility currently employs a high-performance team of engineers, with staff coming from Power-One, ABB and BEL Power Solutions. This facility is the center of excellence for data center and network power products, including rack-mounted Uninterruptible Power Supplies (UPS) and power conversion products. Products for the network power market are under development at this Technology Center and will be released in mid-2021. A new Production Center is located near Bratislava, Slovakia. This facility specializes in the manufacturing of battery and power conversion products for European market. Production of medium format Lithium-ion batteries for the material handling and network power market will be operational by the end of Q2, 2021. The new European team includes industry expert Jochen Schumann as Chief Technical Officer for Green Cubes. Mr. Schumann has over 25 years of demonstrated experience in designing high efficiency AC/DC and DC/DC converters, as well as the management of global engineering teams in the power industry.

With the expansion of both North American and European operations, Green Cubes has a global footprint and now has engineering centers in the United States, India and Switzerland and production facilities in the United States, Malaysia, and Slovakia. An updated brand and new website capture the essence of the company.