Motive Power Solutions

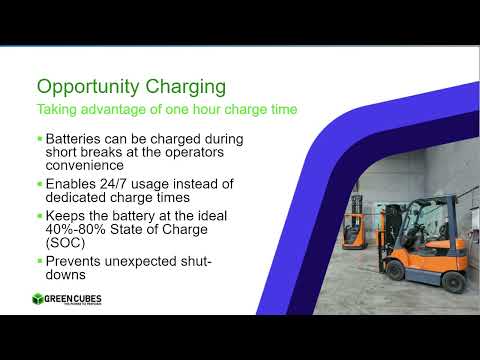

Our Motive SAFEFlex batteries bring unmatched efficiency and reliability to material handling, aviation ground support equipment, and more.

Mobile Power Solutions

Our Mobile Power Solutions redefine energy efficiency for medical and field operations. Experience the freedom of robust, portable power.

Stay Updated with Our

News and Innovations

A Message From the CEO

November 26, 2025

Michael Walsh, CEO of Green Cubes, talks about what powers Green Cubes.

Corporate Overview

November 26, 2025

Learn about Green Cubes Technology in this quick 2-minute video.

Looking for more insights?

Check out our Knowledge Base or read our View all Blogs and View All Videos now.

Plug Into Seamless Power

Experience the ease of our reliable solutions, where powering up is as simple as plug-and-play.

35 Years of Powering Progress

Trust in our decades of expertise and the proven success of our lithium ion batteries to energize your business.

Tailored Power, Total Control

Our deep understanding translates into perfectly suited power management for your entire facility. Green Cubes is one of the leading lithium battery companies.

300 MWh and Counting

Join the ranks of satisfied customers who've propelled us to this impressive sales milestone. Greencubes - USA lithium battery manufacturers.

Support That Never Sleeps

Depend on our mature service team, ready 24/7, to ensure your operations run smoothly around the clock.

Integrated Power, Integrated Success

Leverage our comprehensive ecosystem knowledge for seamless integration and unparalleled operational efficiency.

Industrial Battery Manufacturers in the USA – 35 Years of Powering Progress

Green Cubes is a leading industrial battery manufacturer in the USA, delivering advanced lithium solutions for over 35 years. Our batteries power industries like material handling, healthcare, aviation, and cold storage with unmatched reliability and efficiency. With industry certifications and 24/7 support, we’re the trusted partner for companies seeking tailored energy solutions. Discover why Green Cubes is the preferred choice among industrial battery manufacturers in the USA.

Material Handling

Learn More

Ground Support Equipment

Learn More

Industrial Equipment , industrial lithium battery

Learn More

Healthcare

Learn More

Lithium Battery Cold Storage

Learn More

Powered Carts

Learn MoreChoose Green Cubes for

Industrial Lithium Batteries and Chargers

Green Cubes industrial lithium batteries and chargers are designed not just to power your operations but to do so in a way that significantly reduces your carbon footprint, slashes operational costs, and enhances overall efficiency. With each industry we serve, we ensure that our technology is perfectly aligned with the specific challenges and needs of your equipment.