Material Handling Battery: Reliable Energy for the Long Haul

Green Cubes SAFEFlex lithium batteries are designed for non-stop power and reliability. With over 30 years of expertise and 295 MWh of power in the field, we know what it takes to keep your operations running smoothly. Our material handling battery solutions are built around your needs, ensuring seamless performance that keeps up with the pace of your business.

Whether you’re operating forklifts or automated equipment, our material handling batteries deliver consistent energy and long-term value. With Green Cubes, you get more than just power; you get a partner dedicated to your success, backed by unparalleled support. Let’s power up your efficiency together. To keep your fleet running efficiently, pair them with our Lithium SAFEFlex Chargers — designed for fast, safe, and opportunity charging.

Benefits of Green Cubes' Lithium SAFEFlex Material Handling Batteries

One Battery per Vehicle

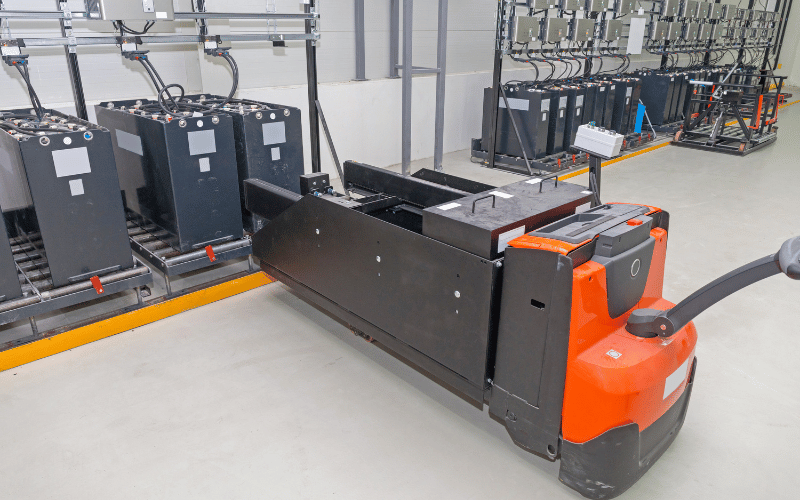

Designed for opportunity charging and a significantly higher cycle life, these batteries eliminate the need for frequent swapping, helping you reclaim your battery room and free up valuable floor space.

Safety & Reliability

Constructed from UL-approved components, these motive power batteries ensure safety and reliability. Voltage, current, and temperature are continuously monitored, with safety managed through contactors. The Lithium Iron Phosphate chemistry used is the safest in the lithium-ion battery category.

Flexible Applications

Suitable for all electric material handling equipment classes 1-3, including small pallet jacks, end riders, center riders, narrow aisle forklifts, 3-4 wheel forklifts, large turret trucks, AGVs, GSE, and industrial electric vehicles. These batteries are also ballasted for heavy counterbalance applications when needed.

Energy & Cost Savings

With a recharge efficiency of over 98%, Lithium SAFEFlex batteries drive significant electrical savings and reduce the damaging effects of heating, contributing to operational cost reductions.

Plug & Play

Featuring a single-point connection, these batteries replicate the simplicity of lead-acid batteries without needing special modifications. Drop-in replacement is straightforward, making battery swaps a thing of the past.

Maintenance-Free

These batteries are sealed and do not require acid, eliminating the need for weekly watering and equalization. The integrated BMS automatically monitors and conditions the battery, ensuring hassle-free maintenance.

Material Handling Batteries: Frequently Asked Questions

35 Years of Powering Progress

Trust in our decades of expertise and the proven success to energize your business.

Material Handling

Learn More

Ground Support Equipment

Learn More

Industrial Equipment

Learn More

Healthcare

Learn More

Cold Storage

Learn More

Powered Carts

Learn MoreCustomer Ratings and Reviews

Stay Updated with Our

News and Innovations

Looking for more insights?

Check out our Knowledge Base or read our Blog now.