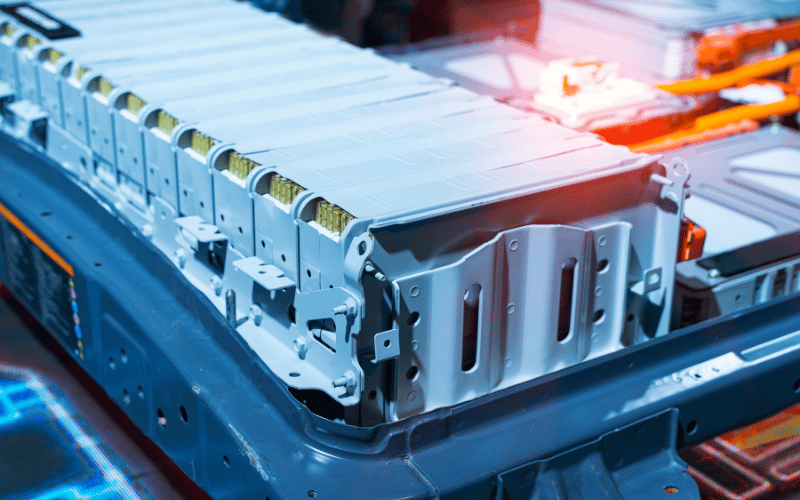

Electric-powered ground support equipment is gaining momentum at airports. In the latest Ground Handling International October 2025, James Muir speaks with Jerry Crump, GSE Sales Director at Green Cubes Technology, about lithium-ion solutions driving feasibility and adoption. Learn how Lithium SAFEFlex powers sustainable airport operations! Read the full article.

About Green Cubes Technology

Green Cubes Technology develops and manufactures safe and reliable electrification solutions that enable its OEM and enterprise customers to transition from Lead Acid and Internal Combustion Engine (ICE) power to Lithium-ion battery power. Green Cubes utilizes proven hardware and software platforms to build the most reliable Lithium power solutions in its industries. With employees across six countries, Green Cubes has been producing innovative, high-performance, and high-quality power solutions since 1986.

For more information about Lithium SAFEFlex PLUS and other battery solutions, please visit greencubes.com or email info@greencubestech.com